Shop Floor Control Real World Implementation

Developing a new mes solution from scratch can lead to failure unless a systematic plan is developed.

Shop floor control real world implementation. Mes emphasizes the information transfer between the production layer and the. In this article i will walk you through the basics of a real time shop floor control system and its benefits in the garment manufacturing sector. Expected benefits often achieved in 6 to 12 months after implementation include quantifiable and qualitative opportunities for improvement. The implementation of shop floor control systems.

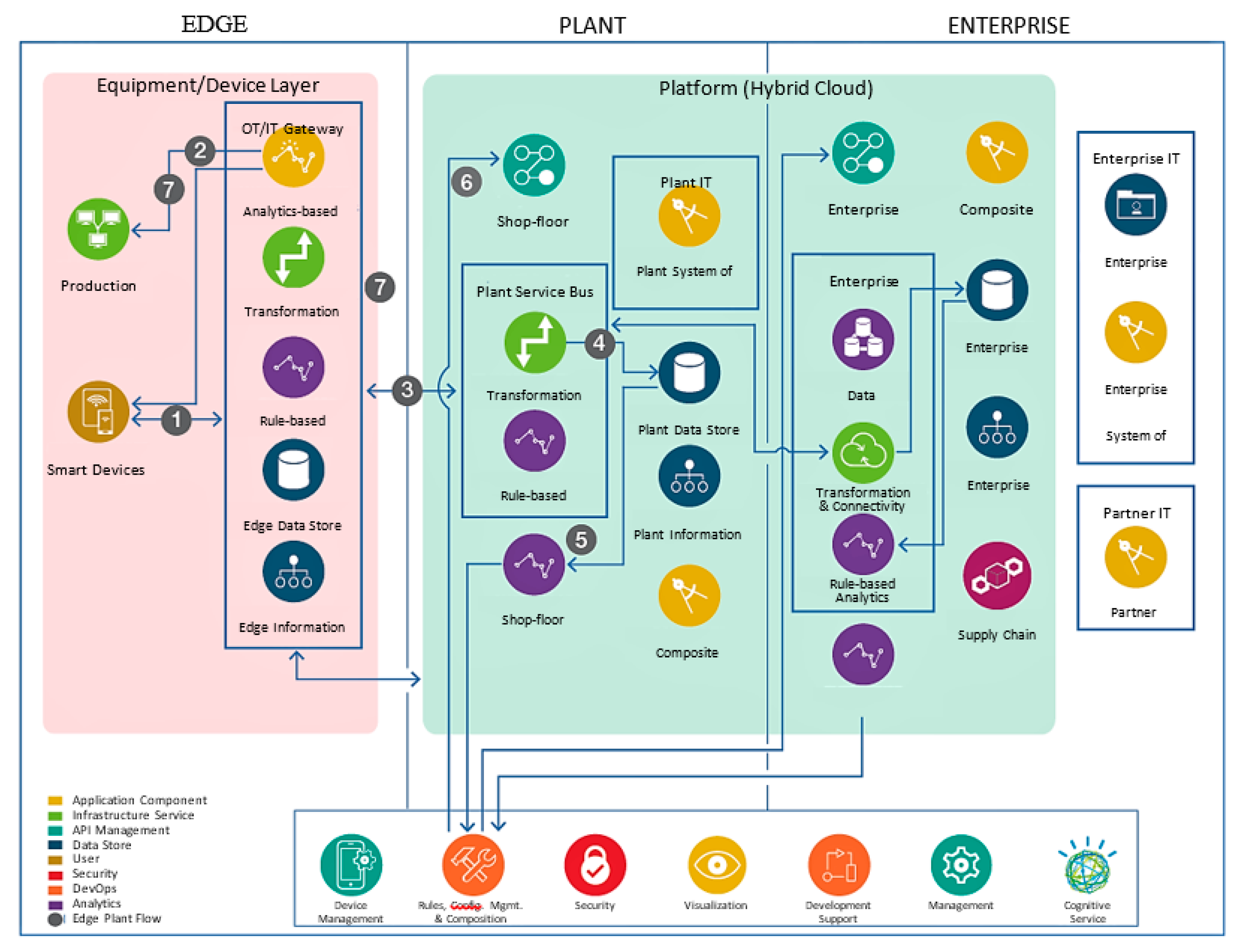

Successful shop floor control demands broad real time visibility to track activities productivity and control costs. Just as the industrial revolution replaced handmade goods software replaces manual efforts with real time data. In the 2012 2013 lns research quality management survey 47 of executives said that a top challenge was having too many disparate quality systems and data sources as a result a roadblock to success that most large and distributed companies experience resides in the. At its focal point this system attempts to offer the best shop floor control and visibility through real time data collection and analysis.

Real time database of shop floor activity. The jd edwards world shop floor control system implements the material plan by managing the flow of materials inside the plant. An unfortunate reality in many quality management strategies is the lack of harmony in it decisions across the enterprise. Alfred bauer richard bowden jim browne james duggan gerard j.

An approach to the implementation of factory coordination and production activity control systems. Also in many industries the shop floor equipment might be custom built and therefore has limited options to interface with the external systems. This creates a single system of record. Apparel manufacturing companies that are aware of the real time system and who feel the accurate and real time data is important for managing and improving the processes are using this kind of systems.

The real time visibility enabled by dynamic shop floor control technology creates a competitive advantage while also increasing plant productivity. At the heart of mes is shop floor control and visual scheduling. The core strength of mes lies in the interface between the factory floor and management. An effectively managed shop floor control system serves as a mediator between production control and the shop floor.

This application is designed for manufacturers to use in the scheduling and control of production as well as the capture of labor materials machines and time used in that production. The shop floor operations are complex and follow distinct operations in every industry.