Shop Floor Production Meaning

The shop floor may include equipment inventory and storage areas.

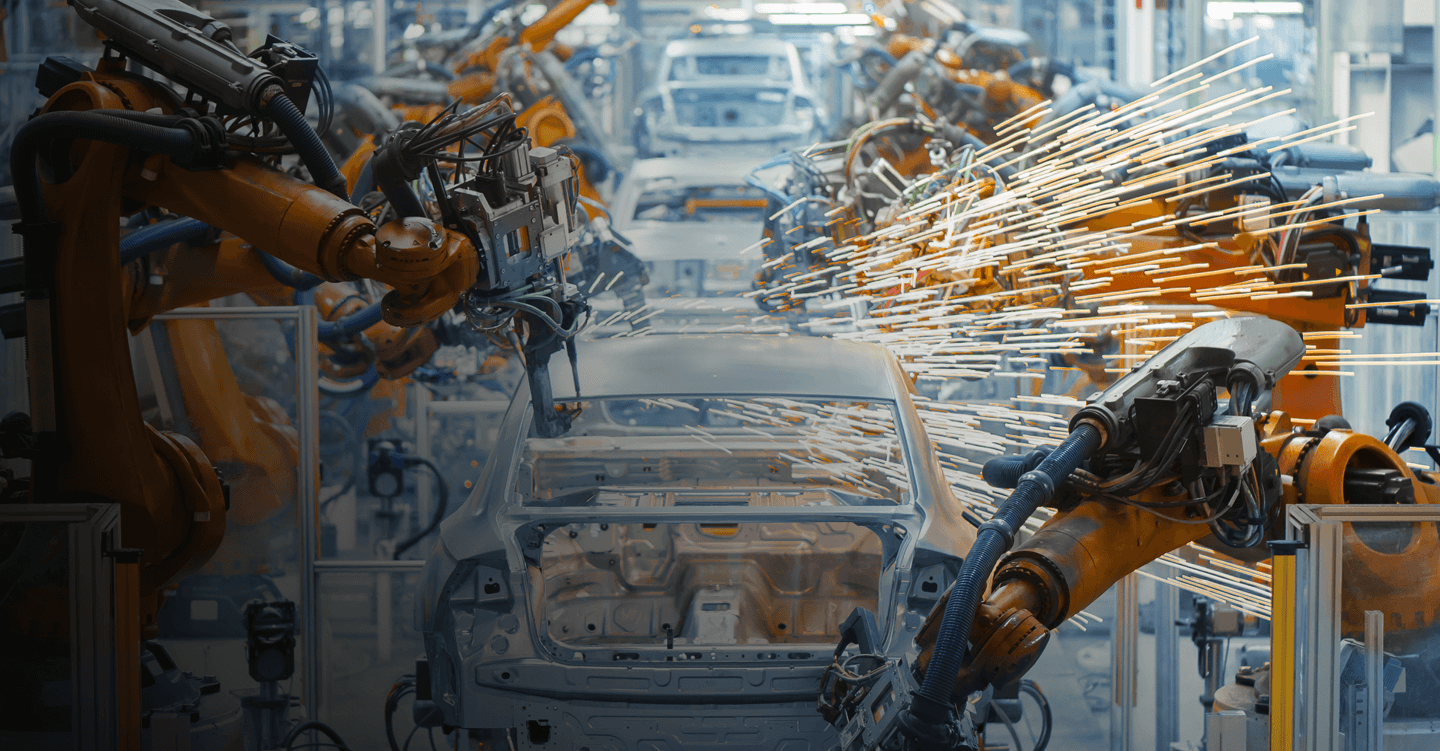

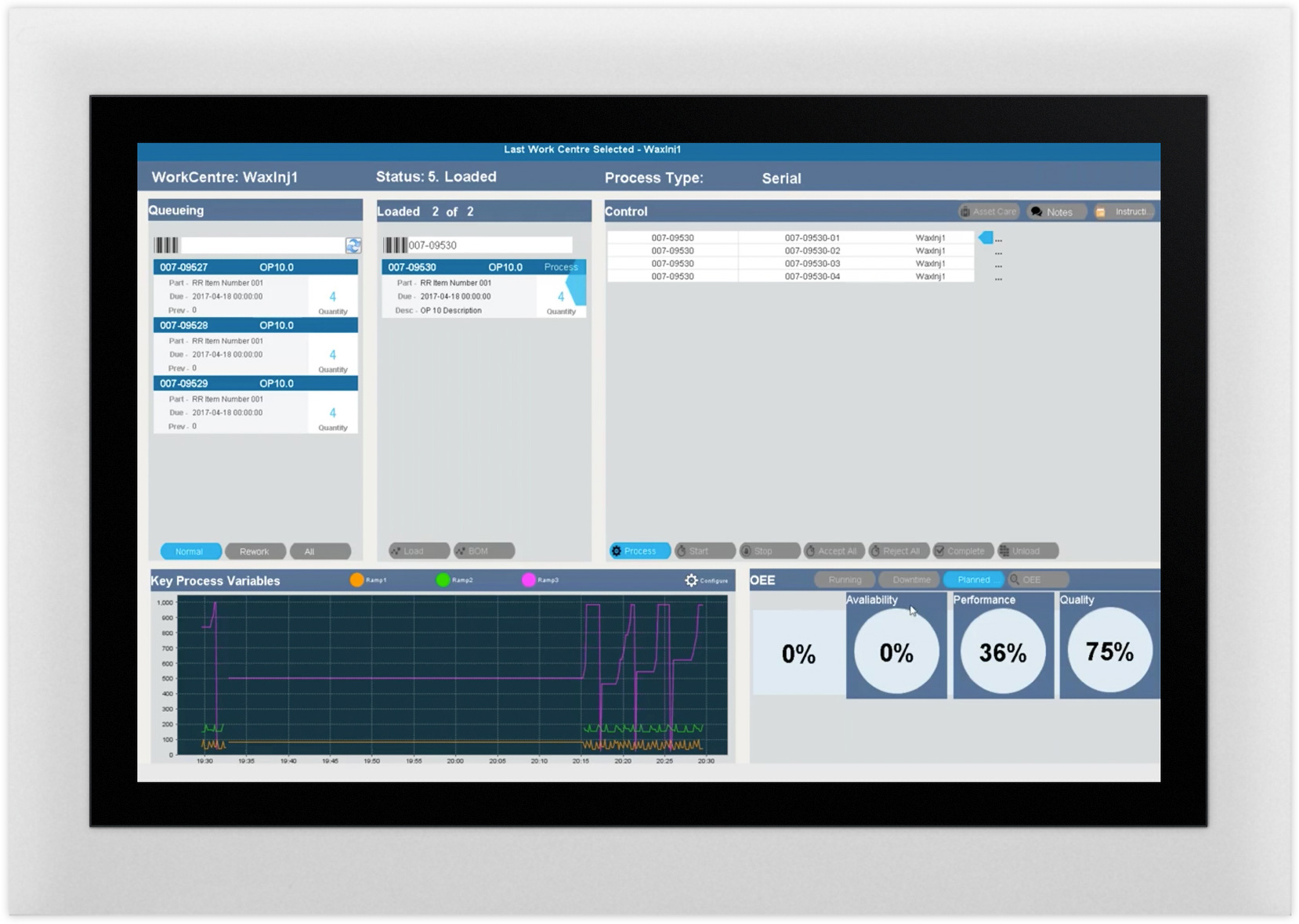

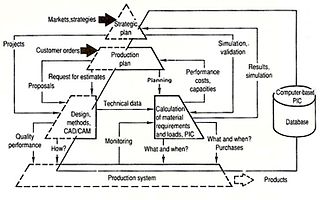

Shop floor production meaning. Shop floor control sfc systems are systems for managing the various components of the manufacturing process. Production operations activity signifies the process of transformation of materials inputs into desired output product services. Industrial relations hr terms a. This type of tool is a major part of business process automation which industrial businesses are using to streamline workflows promote efficiency and improve revenue cycles.

Commerce the part of a factory housing the machines and men directly involved in production. Where people work on machines or the space in a retail establishment where goods are sold to consumers. Among the ordinary workers at. A shop floor is the area of a factory machine shop etc.

The shop floor definition. Workers esp factory workers organized in a union. The ordinary workers in a factory or the place where they work 2. The shop floor is most productive when everyone works together toward the same goal with as little waste and conflict as possible.

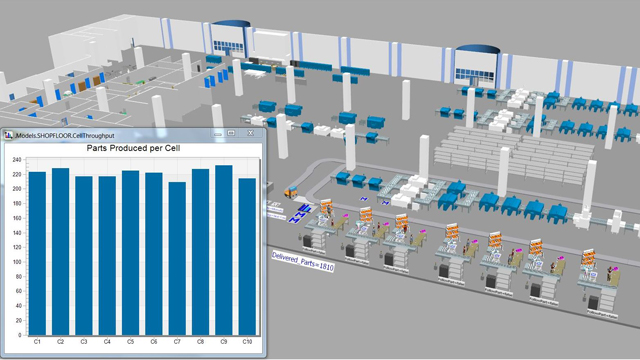

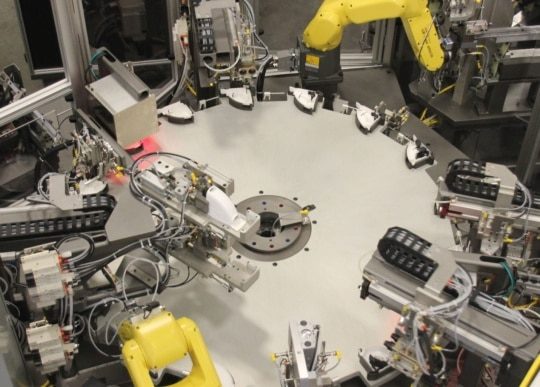

Shop floor the area in a manufacturing facility where assembly or production is carried out either by an automated system or by workers or a combination of both. Shop floor management is concerned with preplanning planning staffing directing monitoring and control of activities that enhance shop efficiency and analysis. On the shop floor management board all employees can see at what stage projects are in and where problems or deviations appear. The shop floor management board provides a good overview of all relevant data current topics and projects in production.

The term shop floor is in contrast to office which is a space that provides accommodation to the business s management. The business dictionary defines shop floor as the area in a manufacturing facility where assembly or production is carried out either by an automated system or by workers or a combination of both. While focusing on work is important it s also crucial to ensure that each staff member feels comfortable as part of a team. An aps system is a requirement for the accurate presentation of key data.

/GettyImages-1186091457-1dfbcb081f6e4bcea9f8fdef15ba55ab.jpg)