Single Face Litho Laminated

Combining strength and beauty this packaging process involves adhering a printed top sheet to a corrugated cardboard substrate.

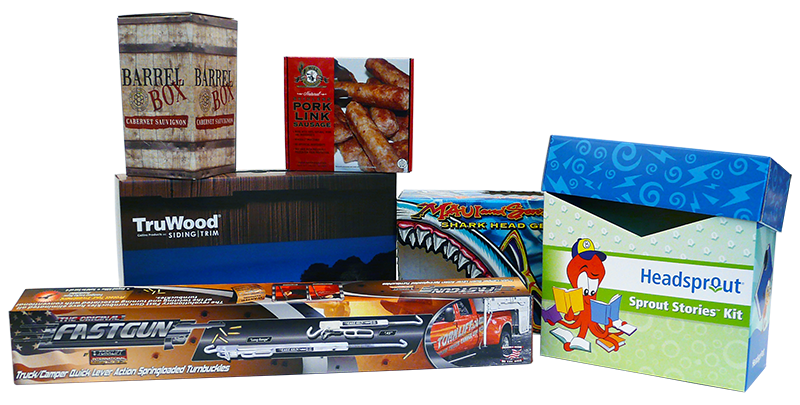

Single face litho laminated. You can also use single face litho lamination for even higher quality printing and a structurally sound package. Single face litho laminate is ideal for heavier products and retail ready displays that call for quality graphics. We have a full complement of laminators die cutters and gluers to produce your retail carton whether just a few or a million. The popularity of custom litho laminated boxes.

The litho laminating process can be sub divided into three main types inline offline and sheet to sheet. The capabilities of any litho laminating line will depend on the exact configuration of units included. 150 230 line screen using offset lithography. Litho laminated alliance was one of the first companies in the united states to begin single face laminating in 1993.

Some litho laminating equipment can also be used for stand alone single face corrugated production or sheeting. The capabilities of any litho laminating line will depend on the exact configuration of units included. Litho print is laminated as top sheet to corrugated single face. Some litho laminating equipment can also be used for stand alone single face corrugated production or sheeting.

Common uses of custom laminated packaging are electronics vitamin and retail packaging and point of purchase displays.